Cảm biến ZW-S7020 2M

Cảm biến ZW-S7020 2M

Liên hệ: 0393.665.382

THÔNG TIN SẢN PHẨM

[Controller] Two options for evolving in-line measurement

For measurement of rattling or inclined “transparent objects or mirror surfaces”

Ultra high-precision type ZW-8000

High-precision in-line measurement of rattling or inclined shiny, thin, or minute parts

Mirror surfaces (inclined or curved surfaces)

Omron’s, unique, white light confocal displacement sensor provides higher resolution measurements of angled or curved and shiny surfaces than traditional laser displacement sensors.

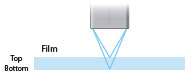

Transparent objects

The ZW-8000 Series can measure the top and bottom surfaces of a thin transparent sheet or film by separating the light reflected from both surfaces, which is difficult with conventional laser displacement sensors.

Minute objects

Thanks to its very small spot diameter, the ZW-8000 Series can measure targets on minute objects extremely precisely, which is impossible with a conventional laser displacement sensor with a large spot diameter.

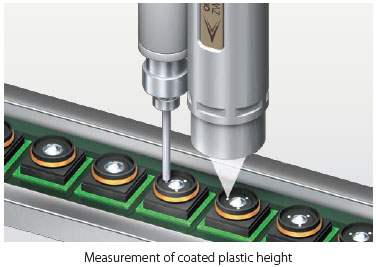

Measurement of “Coarse surfaces” moving at high speed

Ultra high-speed type ZW-7000

Ultra high-speed, stable measurement of diffuse reflective objects during movement

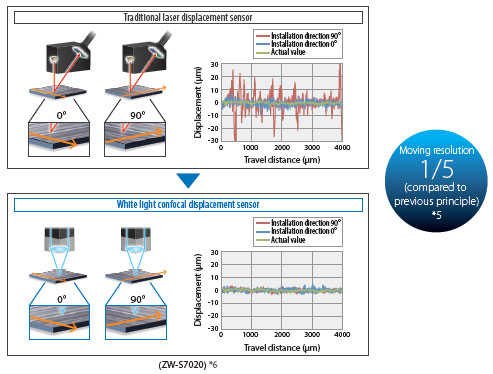

Flatness of coarse surfaces *4

Our white light confocal displacement sensors can provide accurate flatness measurement by tracing an object once without being affected by its excessive reflection, the sensor head direction, nor the material hairline direction, which are difficult to track with a conventional laser displacement sensor.

Shape

Using conventional sensors, the measurement accuracy can be achieved by increasing the averaging times, but downside is that this lowers the profile reproduction accuracy. The ZW-7000 acquires a sharp profile by sampling as fast as 20 μs without averaging, solving this issue.

*1. Typical value of the ZW-S8010/ZW-S7010/ZW-S5010 Sensor Heads.

*2. Typical value of the ZW-S8010 Sensor Heads when transparent objects with refractive index of 1.5 are measured.

*3. Typical value of the ZW-S8010 Sensor Heads

*4. Objects with machining marks or hairline pattern

*5. ZW-S7020.

*6. Please ask Omron sales representative for product data for other than the ZW-S7020.

*7. Please ask Omron sales representative for product data for other than the ZW-S7030.

Note: All measurement graphs represent typical examples. Measurement may be affected by the shape or material of the object being measured.

Before final installation, test the sensor required for the application to validate that the desired measurements have been obtained.

[Sensor head] Head variation for integration into a diverse range of processes and equipment

New ultra-small sensor heads make integration more flexible

The continued evolution of products as they have become thinner, more curved, and more compact has meant that the inspection process has also become more diffcult, and this has necessitated visualization and assembly control in the upstream assembly process.

In response to this, Omron has developed a lineup including both square-shaped type sensor heads with long measurement distance, and ultra-small pen-shaped type (straight or right angle) sensor heads that can be installed in narrow spaces.

Ideal for assembly process

Unlikely to interfere with structures, robots, or stages

Pen-shaped straight type

Measuring range

7±0.3 mm/10±0.7 mm

Pen-shaped right angle type

Measuring range

7±0.3 mm/10±0.7 mm

Ideal for inspection process

Perfect solution for strict inspection accuracy

Square-shaped straight type

Measuring range

10±0.5 mm/20±1 mm/30±2 mm/40±3 mm *

* The 40 mm type is only available for the ZW7000 Series.

[Usability] The white light confocal principle reduces production cycle times through efficient arrangement and movement

Save Time and Money: No need to rotate the sensor

A conventional laser displacement sensor measures the height of an object based on the position of the spot on the receiver.

The machine requires an extra step to rotate the sensor according to the object shape or moving direction.

Our white light confocal displacement sensor can measure from the same installation position while moving in any direction, with no restriction on installation direction.

Flexible fiber cable for easy installation

The controller connects to the sensor head through a 3 mm diameter flexible fiber cable.

The cable has cleared a bending test consisting of 3,000,000 repetitions*2 for reliable application on moving parts.

*2. Omron’s bending test condition: 3,000,000 bends to a 20 mm bending radius

Extension cables for large machines

A 30-m extension fiber cable can be used to extend the distance to up to 32 m, supporting a flexible wiring in a large machine.

Increase throughput: Simultaneous measurements can be achieved using multiple sensor heads

Space restrictions prevent side-by-side installation of many traditional laser displacement sensors. The pen-shaped straight sensor heads can be installed close together to obtain multiple measurements at once, instead of measuring one at a time, thus reducing measurement time.

Further Benefits of White Light Confocal

No discrepancy in the measurement point

With a traditional laser displacement sensor, the measurement position and spot size vary with the height. This means there are times when the position cannot be measured with high resolution due to warping and inclination. With a white light confocal displacement sensor, the measurement point remains the same at any position in the measuring range so that precise measurements can always be made.

Measurement in narrow area and by the wall

When a traditional laser displacement sensor measures the inside of a narrow tube or the height of a small depression, the wall often obstructs the reflected light, and the orientation of the sensor and object must be adjusted many times. A white light confocal displacement sensor can measure the points in narrow spaces or small objects, without changing its installation orientation, because the emitted light and reflected light are positioned along the same axis.

[Usability] The white light confocal principle reduces the time required to implement measures, design, and adjust

Reduced work – EMC measures and thermal design are not required

The sensor head design maintains stable operation in installations with electronic or magnetic noise.

Devices in close proximity and measurement values are not affected by noise or heat from the sensor head.

EMC measures

Thermal design

No laser safety measures required

A white light source *1 eliminates the need for safety measures around the machine and safe use training for workers that are required for a laser light source.

Previously safety measures for laser were required

When a laser displacement sensor was used, a shield around the machine for safety was required and workers had to be trained for safe use.

*1. The ZW-8000 Series is categorized as Class 1.